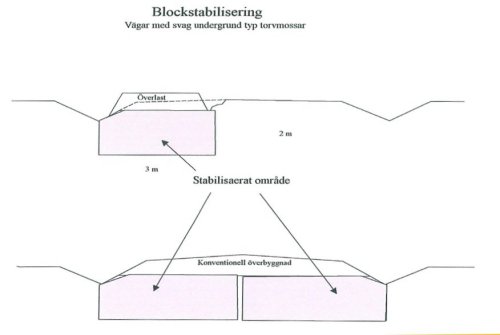

Block stabilization

The stabilized material consists of a mix of Hyttsten and cement.

Procedure:

-

The sub base and road base layers are removed from half of the lane

-

The grinding in of the stabilization material is carried out by insertion at 1m intervalls. The instrument is inserted approximately 2m and is carefully lifted (or tilted) upwards while the stabilization material is carefully superinforced.

-

After the stabilization process, a layer with reinforcement material approximately 1,5m in dept is spread out.

-

After three days, the sub base and road base layers can be spread out on the actual section.

-

When the stabilization process is finished on one lane then the other lane can be stabilized in the same way.

Equipment:

-

Ground stabilization can be carried out with a mix of Hyttsten and cement. When carried out by BDX, the above method is used.

-

BDX method - the material is applied with compressed air and specially-equipped digger in a specific check pattern (or chessboard pattern). The machine's impeller is pressed into the ground and mixes the stabilization material with the original material. After mixing, an extra layer is applied which should settle for three days. After which the sub base is spread and packed.

Another method is the SPECSTAB-method, where a mix of Merit 5000 (GGBS) and cement is used. For more information about this method of stabilization with Merit 5000 please see <www.specstab.se>.